Research and Development

Our Pune-based R&D is a Department of Science & Industrial Research (DSIR) approved best-in-class facility. Over the years, the facility has developed over 325 formulations in-house of which more than 120 products ranging from Dry Powder Inhalers to Nasal Sprays and Bi-layered tablets to Ointments as well as Creams are manufactured at SHL’s own manufacturing facility at Surendranagar, Gujarat & commercialized for international markets like Canada, Ukraine and the CIS, Asia, Africa & FWA.

Formulation Development

Our R&D facility can formulate and develop a wide range of specialized as well as general formulations. Our core strengths include:

- Specialized formulations Dry Powdered Inhalers and Nasal Sprays

- Formulation troubleshooting and Process Development of existing dosage forms

- Development and Optimization of existing formulations

- Tablets [Uncoated/Film Coated/Enteric coated/Sugar coated/Effervescent]

- Capsules [Starting from Size 0 to Size 4 Caps

- Ointments [Ointment/Cream/Gel]

- Excipient compatibility testing

- Quantitative and Qualitative evaluation of proprietary dosage forms

- Infrastructure Support

- Dedicated Area for Raw Material under Lock and key

- Separate AHU system in each area of Formulation and Development

- New Dedicated Facility for Aerosol/MDI Product Development

Analytical Development

Analytical development is a vital component of our R&D and we give special focus to:

- Analytical Method Development for Assay, Dissolution and Related Substances

- Testing of API and Excipients as per Pharmacopeia and by In House Method

- Method Validation – for Assay, Dissolution and Related Substances

- Stability Studies as per ICH Guidelines

- Process and Packaging Validation

- Comparative Study with Innovator for various parameters as per Pharmacopeia and by In House Method

- Documentation

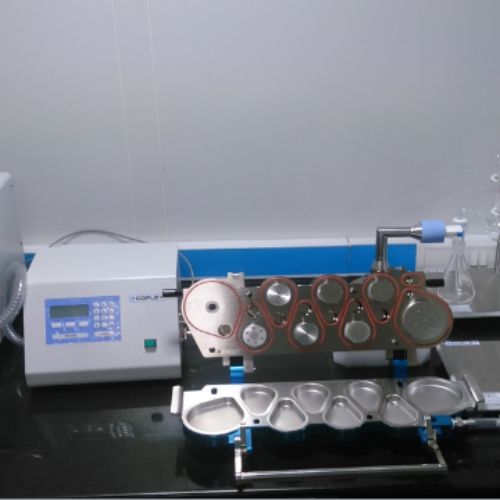

DUSA Apparatus (Copley Scientific, UK)

It is used for the determination of uniformity of delivered dose (UDD) for DPI and MDI products. This test gives us the information about the actual delivered dose uniformity with respect to the label claim.

Next Generation Impactor (Copley Scientific,UK)

It is used for the determination of Aerodynamic particle size distribution (APSD) and fine particle fraction (FPF) of Dry powder inhaler formulation (DPI) and Metered dose Inhalation (MDI) products. This test gives us an idea about the amount of dose reaching to the lungs.

Spraytec (Malvern, UK)

It is used for the determination of droplet size distribution (DSD) by laser diffraction technique i.e. D10, D50 and D90 of Nasal spray and Metered dose inhaler (MDI) products. For nasal sprays, droplets with size less than 120 µm will reach to the site of action (nasal cavity).

Spray View (Proveris Scientific, USA)

It is used for the determination of Spray pattern (Spray area and Ovality ratio) and Plume geometry (Plume angle and Plume width) of Nasal spray products and MDI products. The Spray pattern and Plume geometry gives us the idea about size, shape and angle of the spray which determines the efficacy of the products.